About Us – Revolution Industrial

The driving passion and focus of Revolution Industrial is delivering high quality technical solutions and services that directly meet the customers needs through collaboration with all the relevant areas of the customers business, from board room to shop floor.

Service & Consulting

Revolution Industrial is able to offer a comprehensive range of services from consulting work through to the repair and upgrade of equipment.

With an extensive network of contacts Revolution is able to source parts for almost any machine in the corrugated industry or alternatively offer an upgrade.

The consulting service that Revolution offers is able to look at many facets of the corrugated manufacturing process such as:

- Productivity analysis – Real world advice on how to increase the performance of your equipment

- ROI analysis – Feasibility studies on the purchase of new equipment

- Safety upgrades – Upgrading of Electrical systems to Cat 4

- Machine relocation – Cost, Time, Production Scheduling etc

- Material handling solutions – Increase speeds and reduce costs with throughput analysis

- Leveraging machinery – How existing equipment may be used to target new markets/li>

- Design – Can your boxes be redesigned to run better through your machines

Example Projects

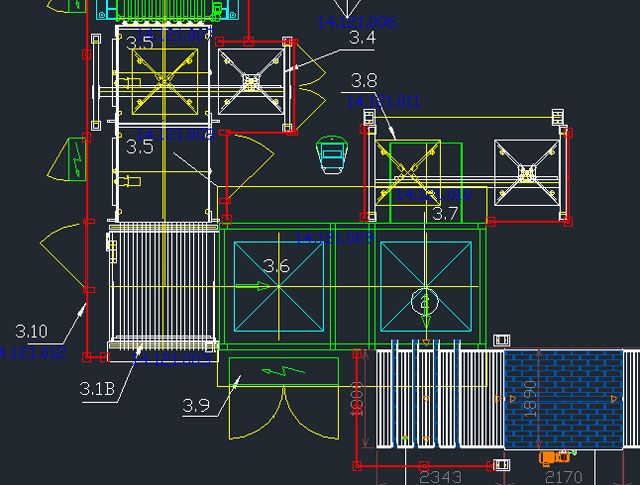

Flat-Bed Die-Cutter Palletisation

The brief in this project was to develop a method of breaking and palletising die-cut blanks off the back of a Flat Bed diecutter.

The result was a line that could reconfigure bundles regardless of the die orientation to a variety of pallet layouts from 1U1 and 24U1 through to 16S1 or 4S1 strapped.

The outcome was a line that could (as displayed in the above photo) create a 16S1 pallet without inhibiting the speed of the Flat-Bed Die-Cutter (In this case 5,000 sheets per hour).

Through the use of Pre-Feeders and Palletisiers, this line runs with 2 operators.